Do you Know the Key Points When API Gage Practice?

1.About FYOU PMEC

FYOU PMEC are authorized to represent the products of the three top API Gauge manufacturer in China, which are subsidiary facilities of state-owned corporations and are API licensed. All the gauges come with the calibration certificates traceable to NIM (National Institute of Metrology, China ) and valid for API audit. To find out more information on our products, please contact us by e-mailing:sales@fyougauges.com. We try to provide the best possible solution for you as quickly as we can.

- About the API and the quality request

The American Petroleum Institute (API), head quartered in Washington, DC, USA is a world leader in the development of standards for all aspects of the oil and natural gas industry. When using API sanctioned gages for the inspection of products or calibration of other gages, it is critical that the user have a high quality gage, manufactured using the latest manufacturing and inspection technology available. Gages should be manufactured so that they meet or exceed API specifications.

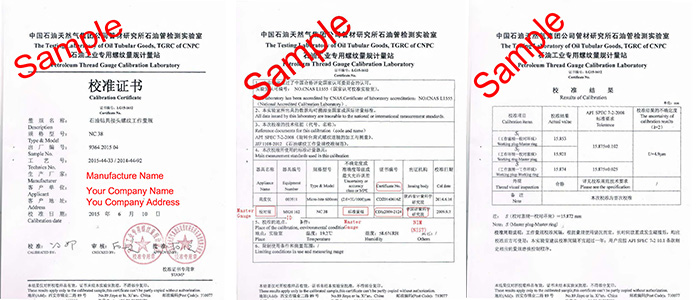

3.About the Calibration Certificates.

Each API working gage shall be accompanied by a certification listing the values with dimensions measured for each critical element, as well as a measured standoff to a certified master gage. Each API master gage shall be accompanied by a certification from an API qualified agency such as the National Institute of Metrology (NIM) located in Beijing, China, the National Institute of Standards and Technology (NIST) located in Gaithersburg, Maryland, USA, or the National Physical Laboratory (NPL) located in the United Kingdom as described in the API specifications. For API Specification 5B, the API approved certifying agency shall perform a full inspection on all critical elements as well as a mating standoff, and provide a report detailing the results of the inspection. For API Specification 7, the API approved certifying agency shall perform a full inspection on all critical elements as well as a standoff against the appropriate regional or grand master gages and a mating standoff. A certification shall be provided detailing the results of the inspection.

- About the API Gage Tolerance.

The gage tolerance defined by API is designed to allow the gage manufacturer tolerance for manufacturing the gage while still providing the end user with tolerance for wear of the gage. Due to the desire for maximum wear life of gages, it is often requested that gages be manufactured on the plus side of the tolerance. Manufacturing to the plus side of the tolerance does not always provide desirable results. It is possible that manufacturing to the plus side of the tolerance will lead to one laboratory performing inspection and standoff near the maximum limit while another laboratory, using different master gages will find that the gages exceed the allowable tolerances and they will question the validity of the gages. This situation can arise very easily for API Specification 5B gages because the taper ratio is 16:1 and even small differences in diameter can result in large differences in standoff. For this reason, it is FYOU PMEC’ practice to provide all gages as close to nominal size as possible. When there is a difference between the API accredited manufacturer’s reported results and another API accredited laboratory’s reported results, it does not mean that the gages are out of tolerance and should be rejected. It simply means that the two inspecting laboratories have master gages which differ in size from one another. In cases such as this, the inspection results provided by the API accredited manufacturing and inspection facility should be accepted and used with the gages. It is also recommended that the results provided by the local laboratory be recorded for future comparison when checking for wear. Manufacturers of product threads shall conform to the gauging requirements as stated in API Specification 5B, Fifteenth Edition, April 2008 Paragraph 6.1.2.