How do you use an internal thread taper gauge?

FYOU PMEC, One Stop Shopping for Threading and Gaging Solutions!

FYOU PMEC’ API Thread Gauges、Premium Connection Gauges ,and ANSI/ASME Thread Gauges have been used worldwide and receiving the highest quality reputation. And our supplier plants are licensed to API Spec5B, API Spec7-2 and API Spec11B.

FYOU PMEC, supply a complete line of Thread Gauges listed in the API Spec 5B ,API Spec 7-2, and API Spec 11B. Also, we provide its measuring gauges. To find out more information on our products, please contact us by E-mail: sales@fyougauges.com. We will provide you the best possible solutions for you as quickly as we can.

1.Definition

For round threads and line pipe threads, taper shall be defined as the increase in the pitch diameter of the thread, in inches per inch (millimeter per millimeter) of the thread. For buttress threads, the taper is defined as the change in diameter along the minor cone of the external threads and the major cone of the internal threads. On all threads, taper tolerances are expressed in terms of “inch per inch of the thread” (“millimeter per millimeter of the thread”) and taper deviation shall be determined accordingly. The measurements are made for the specific interval lengths and the observed deviation shall be calculated to the inches per inch (millimeters per millimeter) basis.

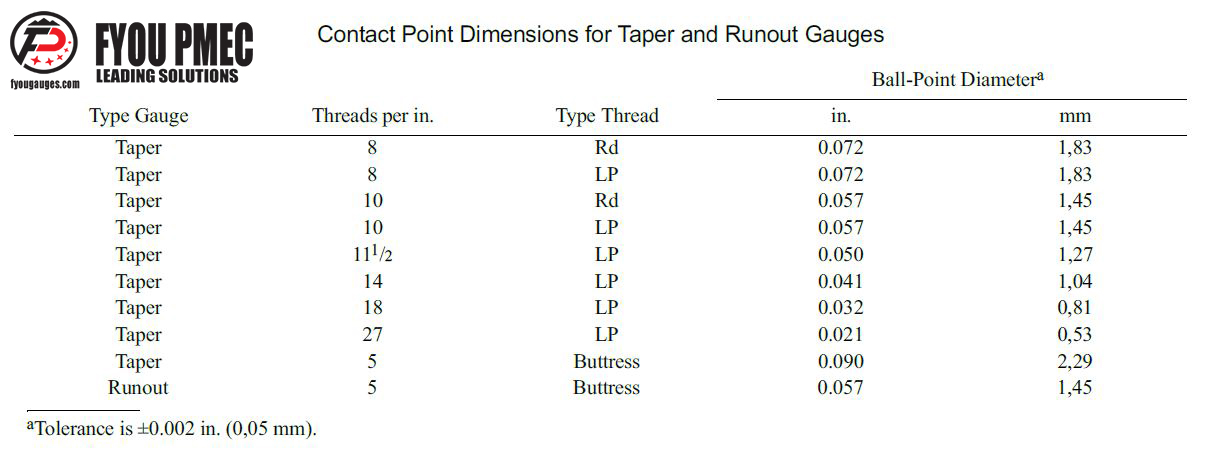

2. Gauge Contact Points

The contact points of taper gauges shall be of the ballpoint type with diameters in accordance with the following table. For line pipe and round threads, the diameter of the contact points are such that they contact the thread flanks at the pitch cone, approximately, rather than the minor cone. For buttress threads, the dimensions of the contact points are such that they contact the minor cone of external thread and the major cone of the internal thread.

3. INTERNAL THREADS IN SIZES 41/2 AND LARGER

- Taper Gauge

The taper of internal threads in sizes 41/2 and larger shall be measured with an internal-taper gauge

- Procedure (Taper Gauge)

The ball point in the fixed end of the gauge shall be placed in the groove at the last perfect thread position and the ball point on the plunger in the groove diametrically opposite. The fixed point shall be held firmly in position, the plunger point oscillated through a small arc, and the dial indicator set so that the zero position coincides with the maximum indication. Similarly, successive measurements, at the same radial position relative to the axis of the thread, shall then be taken at the required intervals toward the large end of the internal thread for the full length of perfect threads. The taper in the first interval of perfect threads shall be measured. The difference between successive measurements shall be the taper in that interval of threads.

4. INTERNAL THREADS IN SIZES SMALLER THAN 4 1/2

- Taper Gauge

The taper of internal threads in sizes smaller than 41/2 shall be measured with an internal-taper gauge.

- Procedure (Taper Gauge)

The ball point on the adjustable arm of the gauge shall be placed in the groove at the last perfect thread position and the ball point on the pivoted arm of the gauge in the groove diametrically opposite. The fixed point shall be held firmly in position, the pivoted point oscillated through a small arc, and the dial indicator set so that the zero position coincides with the maximum indication. Similarly, successive measurements, at the same radial position relative to the axis of the thread, shall then be taken at the required intervals toward the large end of the internal thread for the length of perfect threads. The taper in the first interval of perfect threads shall be measured. The difference between successive measurements shall be the taper in that interval of threads.

How to Order?

When you order, please let me just know the thread type and range need be measured, we will provide you the best solutions and best quotations. More details or any questions please contact: sales@fyougauges.com or WhatsApp/Wechat: +86 13962168423